Bipv Solar Modules: Integration, Performance, and Design Best Practices

You can turn building surfaces into power sources without sacrificing design. BIPV solar modules replace or integrate with roofs, façades, and glazing to generate electricity while serving as actual building materials, cutting energy costs and preserving aesthetics.

Expect practical options for new construction and retrofits that blend function and form. The article will walk through how BIPV works, where it fits best, and the real advantages—so you can decide whether integrating solar into the building envelope suits your project or property.

BIPV Solar Modules Overview

BIPV solar modules replace or become part of building elements like roofs, façades, and glazing while producing electricity. You’ll read how they differ by form factor and material, what technologies are common, and the trade-offs versus conventional panels.

Definition and Key Features

Building-integrated photovoltaics (BIPV) are photovoltaic products designed to serve as building materials while generating electricity. You can install them as roof tiles, curtain wall panels, skylights, or solar glass that doubles as a window.

Key features include structural integration, aesthetic customization (color, translucency, pattern), and dual functionality—thermal or daylighting performance plus power generation.

BIPV often reduces material and mounting costs because modules replace cladding or glazing. You should expect lower per-watt efficiency than optimized rooftop modules in many cases, but gain in reduced labor and improved architectural coherence. Durability, fire rating, and building-code compliance matter more for BIPV than for standard modules.

Types of BIPV Technologies

Several BIPV types suit different parts of a building. Crystalline silicon modules are used as panels or shingles for roofs and façades; they offer proven efficiency and longevity. Thin-film (CIGS, CdTe, amorphous silicon) provides flexible, lighter-weight options and better aesthetics where uniform appearance or translucency matters.

Transparent or semi-transparent solar glass uses thin-film or micro-PV cells laminated into insulated glazing units for windows and skylights. These trade some transparency for power and can improve solar control when paired with coatings.

Other specialty formats include building-applied PV (BAPV styled to blend in), solar tiles that mimic traditional roofing materials, and custom curtain-wall panels with integrated mounting. Your choice depends on load capacity, fire and wind ratings, visual requirements, and desired power density.

Comparison with Conventional Solar Panels

Conventional rooftop PV (BAPV) focuses on maximizing power per area and lowest installed cost, while BIPV prioritizes integration and multifunctionality. Expect conventional modules to offer higher module efficiency and lower cost-per-watt because they don’t need architectural matching or structural re-certification.

BIPV reduces secondary costs by replacing building materials and can improve building envelope performance (insulation, daylighting). It usually requires more complex design coordination—structural, electrical, and façade engineering—and can incur higher permitting and custom-manufacturing lead times.

Operationally, maintenance access and cleaning can be more challenging for integrated elements. You should weigh lifecycle costs, aesthetics, and energy yield per installed square meter when choosing between BIPV and conventional PV.

See also: Wearable Technology Innovations in Healthcare

Applications and Advantages of BIPV

BIPV replaces or integrates with standard building elements to generate electricity while serving structural or aesthetic functions. You get power generation combined with material savings, design flexibility, and potential regulatory or incentive benefits.

Building Integration Methods

You can integrate BIPV into roofs, façades, windows, and canopies.

- Roof integration: replace shingles or standing-seam metal with BIPV roofing panels that provide weatherproofing and electrical output. These suit new construction and re-roof projects where load and flashing details are planned in advance.

- Façade integration: use BIPV curtain walls or cladding panels to generate electricity without separate mounting racks. They work well on south- and west-facing elevations for higher irradiance.

- Glazing and skylights: choose semi-transparent BIPV modules for windows and atria to admit daylight while producing power; balance visible transmittance (VT) and module efficiency when specifying glass coatings and cell layout.

- Canopies and shading devices: mount BIPV as sunshades or parking canopies to provide shade, on-site generation, and sometimes microclimate control.

Plan for electrical routing, fire separation, and access for cleaning during design to avoid retrofit complications.

Architectural Design Considerations

You must coordinate structural loads, waterproofing, and thermal performance early in design.

Specify module size and shape to match façade module gridlines or roof battens to avoid excessive cutting and waste. Consider module color, translucency, and edge framing to meet your visual goals without compromising output.

Pay attention to thermal bridging and condensation; integrate vapor barriers and thermal breaks where BIPV replaces insulated assemblies.

Meet code requirements for fire rating, egress, and impact resistance; for high-rise façades, provide testing evidence for cladding systems with integrated PV.

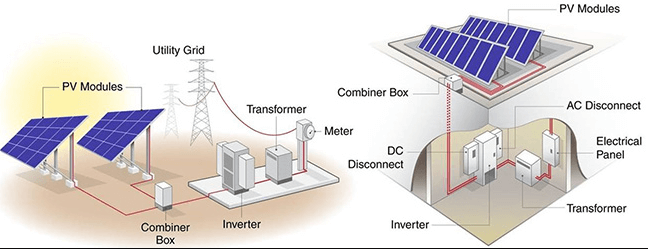

Coordinate with the electrical engineer for inverter placement, DC combiner boxes, and monitoring so you can minimize DC run length and optimize performance.

Energy Efficiency and Performance

BIPV can contribute to on-site generation and reduce building energy purchases when sited and oriented correctly.

Assess orientation, tilt, and shading: south-facing façades and roofs yield the highest annual kWh in most temperate climates. Use performance modeling to estimate annual output and compare BIPV options (monocrystalline, thin-film, bifacial) for tradeoffs between efficiency and aesthetics.

Consider thermal effects: BIPV can lower cooling loads when used as an external shading element, but if it replaces insulated roof decking, verify net energy balance with detailed heat-transfer analysis.

Plan for system monitoring, routine cleaning, and accessible inverters to preserve long-term performance and warranty compliance.

Environmental Impact and Sustainability

BIPV reduces lifecycle material redundancy by replacing conventional cladding or roofing materials with energy-generating assemblies.

Quantify embodied carbon savings by comparing the combined BIPV assembly to separate PV + conventional materials; this often shows lifecycle greenhouse gas benefits, especially when modules use low-carbon manufacturing.

Design for recyclability and end-of-life: choose modules and mounting details that allow disassembly and material separation to ease future recycling.

Leverage incentives and green building credits: BIPV can contribute to net-zero targets, LEED credits, or local renewable energy mandates when documented with metered output and specification records.